The rotating scroll and the fixed scroll are the core components of the scroll compressor, and their design directly affects the gas compression efficiency. Understanding the working principles and design features of these two scrolls will help optimize the performance of the scroll compressor.

1. Structural principle

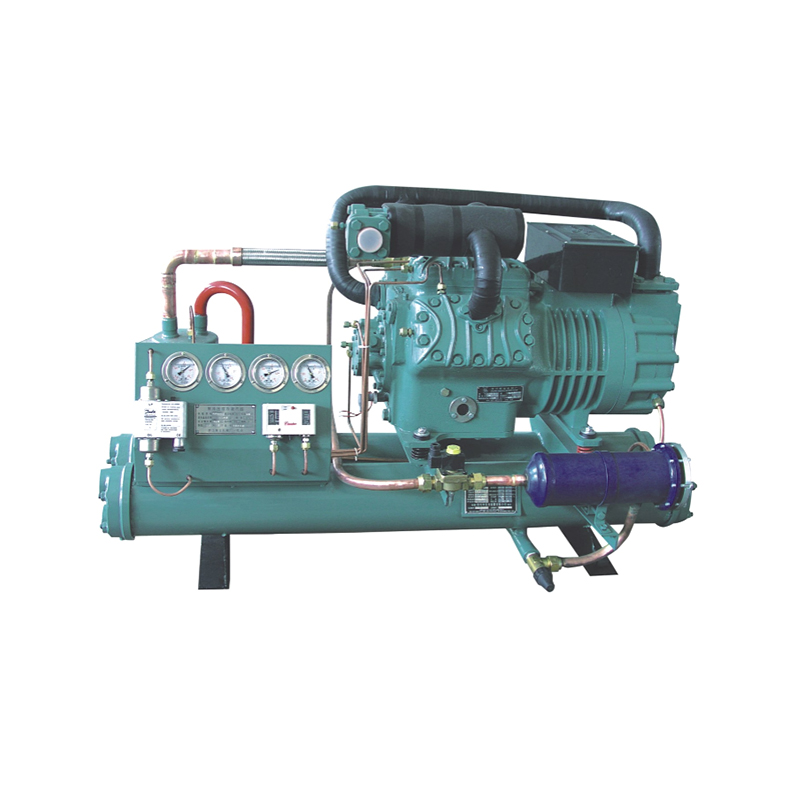

The scroll compressor consists of two scrolls: one is a fixed scroll and the other is a rotating scroll. The rotating scroll rotates along the contour of the fixed scroll to form multiple gas compression chambers. During this process, the gas is sucked in from the outside, gradually compressed and discharged through the scroll chamber. The shape, size and relative position of the scroll will affect the flow and compression process of the gas in the compression chamber.

2. The design of the scroll

Vortex shape and depth: The shape of the scroll determines the flow path of the gas in the compression chamber. A deeper scroll chamber can accommodate more gas, but if it is not designed properly, it may cause uneven gas flow and increase compression loss. Optimizing the scroll shape can achieve higher compression efficiency.

Gap between scrolls: The gap between scrolls is also a key factor. Too large a gap can cause gas leakage and reduce compression efficiency; while too small a gap may cause friction and wear. Therefore, a reasonable gap design helps to improve the performance and reliability of the compressor.

Material selection: The material of the scroll disk is directly related to its durability and thermal conductivity. Using high-strength, wear-resistant materials can extend service life, reduce maintenance costs, and improve heat exchange efficiency.

3. Overall impact

In summary, the impact of the design of the rotating scroll disk and the fixed scroll disk on the gas compression efficiency is obvious. By optimizing the shape, gap and material of the scroll disk, the performance of the scroll compressor can be significantly improved. This not only improves energy efficiency, but also reduces operating costs, bringing greater economic benefits to users.

In the research and development of scroll compressors, paying attention to the design details of the scroll disk will be an important way to achieve efficient and reliable compression. With the advancement of technology, future scroll compressors will pay more attention to the scientific nature of their design to meet the growing market demand.